What are the cabinets electric hinged metal, an overview of models

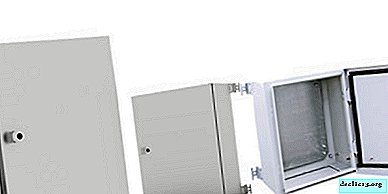

Today, metal furniture is extremely in demand both at home and at large industrial facilities. It is used to place electrical units and ensure the safety of metering devices, uninterruptible power supplies, distribution nodes, communication systems. Further, what a high-quality electric hinged metal cabinet should be like to provide the equipment with reliable protection against negative factors from the outside.

Purpose and characteristics

Cabinets for electrical equipment only at first glance seem to be products of a narrow scope. In fact, such products can be found both in everyday life and in industrial enterprises, because any room that is connected to the power supply system is equipped with a metering device. This is a rather fragile equipment, which certainly must provide the right conditions for functioning. Reliable metal boxes with locking mechanisms and a high degree of resistance to atmospheric phenomena (rain, high humidity, sharp gusts of wind) will help to do this. It is equally important to reduce the degree of influence of other environmental factors that could harm or interfere with the normal functioning of electrical equipment.

Thus, the boxes for electrical equipment are very relevant highly functional products, without which it is difficult to imagine the normal operation of many varieties of electrical equipment. But products of this kind are very diverse in operational parameters, so before purchasing a model, it is important to study its features, dimensions, level of functionality.

Manufacturers provide customers with the opportunity to purchase all the mounting accessories, circuit board, flange, and the cabinet itself in a single set. You can also pick up a variety of false panels, allowing you to make boxing more pleasing in appearance. In addition, many models have pre-prepared holes on the rear wall, special door rails, so the implementation of electrical work is practically not complicated. And thanks to the presence of locking mechanisms of varying degrees of reliability, it is possible to reliably protect the internal contents of the box with the mounting rail from vandals.

Types and Features

Today in the domestic market floor and wall boxes are available for purchase. The first (floor) are installed directly on the ground or any kind of coating (concrete, brickwork, logs), which lined the floor in the room. The second (wall) are mounted on the wall surface without touching the base. To choose the right type of wall cabinet for electrical equipment, you need to familiarize yourself with all the specifications.

Based on the features of installation, manufacturers offer the following types of metal boxes:

- hinged boxes are a great option for rooms where there is no way to organize a niche, as well as for installing electrical equipment on the street under a canopy. Due to the presence of special holes on the back wall, the cabinet is suspended on the wall surface without the risk of collapse of the structure;

- built-in drawers with mounting rail. They require a special niche in which they are mounted. It is relevant for the placement of uninterruptible power supplies, electricity meters in a small room, where a niche is present or its creation will not cause special difficulties, as well as where to mount a hinged shield can be problematic due to its excessive dimensions. Built-in drawers can have standard sizes or can be made to order with a non-standard width, depth, height.

Recessed

Recessed Mounted

MountedBased on the design features, distinguish metal models:

- with a window on the door to take readings from the meter. No need to open the door of the product significantly prolongs the life of the box, as well as the equipment inside it. For units, optimal operating conditions are created, a constant temperature regime is maintained;

- with an electronic display showing the value on the meter;

- with a dull facade - in this case, it is possible to clarify the readings of the counter working inside the box only by opening the latter;

- with the ability to seal the metering device and without it;

- with pre-arranged mounting holes on the rear wall of the box and without them. In the presence of such holes, the installation of the box will take a minimum of time;

- with locking mechanism (latch, padlock, mortise, combination lock) and without it. If expensive equipment is placed inside the box, the design must necessarily have a reliable locking mechanism. Otherwise, you can expose its contents to the risk of being stolen. The most reliable are combination locks, since padlocks can quickly break under mechanical stress.

The more functions and additional components a model has, the higher will be its cost.

With a blank facade

With a blank facade With a window

With a window With electric board

With electric boardCharacteristics

Steel cases of cabinets for electrical equipment have different thicknesses (from 0.8 to 1.5 mm). They are equipped with a mounting plate, the thickness of which is 2 mm. Models of such a plan are able to withstand the temperature difference in the range of -50- + 80 ° C, therefore they are suitable for installation both indoors and outdoors (but under a canopy for greater reliability).

Metal cabinets with a mounting rail and a locking mechanism are characterized by a high degree of reliability, subject to all rules and standards of operation. They are resistant to mechanical wear, as they are made using high-quality sheet steel, which is coated with a protective layer of powder polyester paint. This technology of creation gives the design heat-resistant properties.

Due to the presence of different levels of protection against humidity, you can choose the model that is relevant for specific conditions. So for installing an electric meter in everyday life, you can limit yourself to a metal box with the IP20 marking, which can prevent the risk of dust particles exceeding 12.5 mm in diameter getting inside. But to install such a product on the street in the open air is not worth it, since increased humidity can harm it. For such purposes, you will need to choose a model with a higher degree of moisture protection (marking from IP54).

A metal distribution cabinet is not afraid of corrosion due to exposure to high humidity, as it has only four welds and is equipped with a cast polyurethane sealant. The same quality provides the basis for high strength products.

The dimensions of such products with a locking mechanism determine the level of its capacity and certain design features. The metal distribution cabinet is often large in size, so it is extremely rarely mounted in small rooms. For example, in corridors, it is important to use only built-in cabinets.

The cost of a metal shield of a hinged type is determined by its design features, dimensions, purpose.

Dimensions and nuances of accommodation

Boxes to ensure the safety of electrical components are of different weights. This indicator varies between 2-20 kg depending on the scale of the model. The thickness of the metal walls is 0.5-0.8 mm. The higher this indicator, the more reliable the box is in terms of resistance to mechanical stress. The thickness of the mounting plate made of steel is 1-1.5 mm.

The standard dimensions of metal hanging cabinets for placing metering devices, uninterruptible power supplies and other types of electrical equipment are presented in the table.

| Parameter | Hinged structures |

| Depth mm | 330-550 |

| Width mm | 600-700 |

| Height mm | 500-900 |

If necessary, get a model of a non-standard configuration or size, you will need to use the custom-made service. This will require material investments and some time, but the model will correspond to specifically relevant parameters.

Metal cabinets of a hinged type with a mounting rail are convenient in that they do not require specific preparation of the site for installation. The main thing is not to make a mistake in choosing the place where the input of the power line is suitable and the comfort of the wiring of the mains branches from the equipment in the panel is ensured.

A distribution cabinet of various sizes is mounted in accordance with certain standards. Manufacturers recommend adhering to a certain installation height:

- for boards according to PUE, the optimal installation height is from 0.4 to 2.2 m from the level of the base;

- for switchgear panels for electricity meters, the optimal installation level is at 1.7 m from the floor.

Remember, it is strictly forbidden to place the box with wires near points with increased fire hazard, open fire. If the box is characterized by a low degree of resistance to moisture and precipitation, it should not be placed outdoors. Even a canopy will not always protect the electrical equipment inside the product from the risk of damage. Models with a low degree of resistance to moisture are best installed indoors, in extreme cases - under a canopy.

Criterias of choice

When choosing an electric hinged metal cabinet with a mounting rail, it is important to take into account the following points:

- the presence of cable holes pre-prepared by the manufacturer (incoming and outgoing from the box). The absence of such elements will complicate the installation work somewhat, require special equipment at work, as well as certain skills from the master;

- the presence of a window or display for taking readings from the meter. It is these models that are more convenient to use, since they allow a person to neglect the procedure for opening a box, if necessary, provide the counter with the controller;

- the ability to install a seal on the meter. An extremely important characteristic for those cases when the operation of the meter without this procedure is not permitted by the service provider;

- number of circuit breakers that can fit inside the cabinet. Metal cabinets with a larger capacity (54 and above the machine) will cost more.

It is equally important to carefully inspect the product, analyze its quality. The seams should be smooth, without chips, smudges of metal, other defects. The powder coating should have an even layer without tubercles and grooves. Only then will the locker be able to cope with the functions assigned to it. If the visual inspection did not allow to detect any defects, it is better to ask the seller for documents for the selected model. A quality certificate and detailed manufacturer's instructions are included with each quality product.

Video

Photo